|

GFP Tools Ltd offer a Toolmaking service specialising in 3D CNC Milling, and CNC Spark Erosion. This includes Injection Mould Tool manufacture, Die Casting, Forging and Precision machining. We provide machining to cores and cavities, complete with manufacture of any electrodes if required. We can also assist with any aspect of bolster manufacturing.

Our Spark Erosion capabilities include manufacture of all types of electrodes with full CNC 4-axis machine complete with an Erowa tooling system. The whole manufacturing process is palletised throughout.

Below are examples of work we have carried out:

|

|

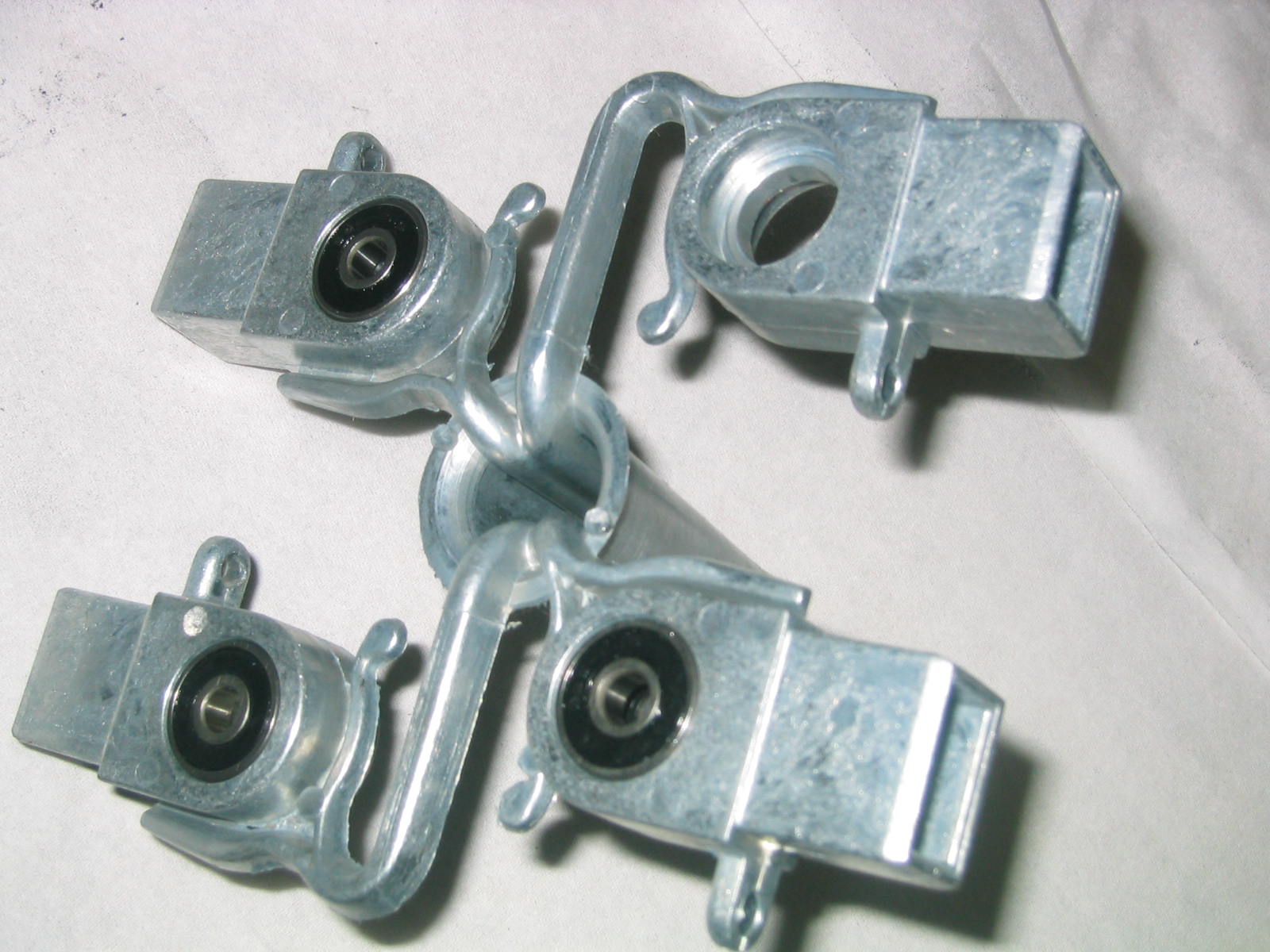

A 4-impression zinc diecast tool, cast to very high tolerances to enable push fit of bearings without the requirement for machining. |

|

|

A Copper Electrode, used to produce a cavity for an injection mould tool. This is a good example of a 3D electrode and 3D CNC Spark Erosion because the land detail had to be produced over 360 degrees, even across the joint line (equator). |

|

|

Turned cores and pegs used in the forging industry. |

|

|

An example of a forging die used to produce security hardware. This product also requires a press tool to clip profile and pierce slot detail. |

|

|

An example of a hot brass stamping die, used in a vice action press. This die was milled complete on our CNC machining centre, from an iges file machined lights out unmanned . |

|

|

Typical injection mould tools which we have produced all core and cavity details, c/w manufacture of electrodes and CNC Spark Erosion. |

|

|

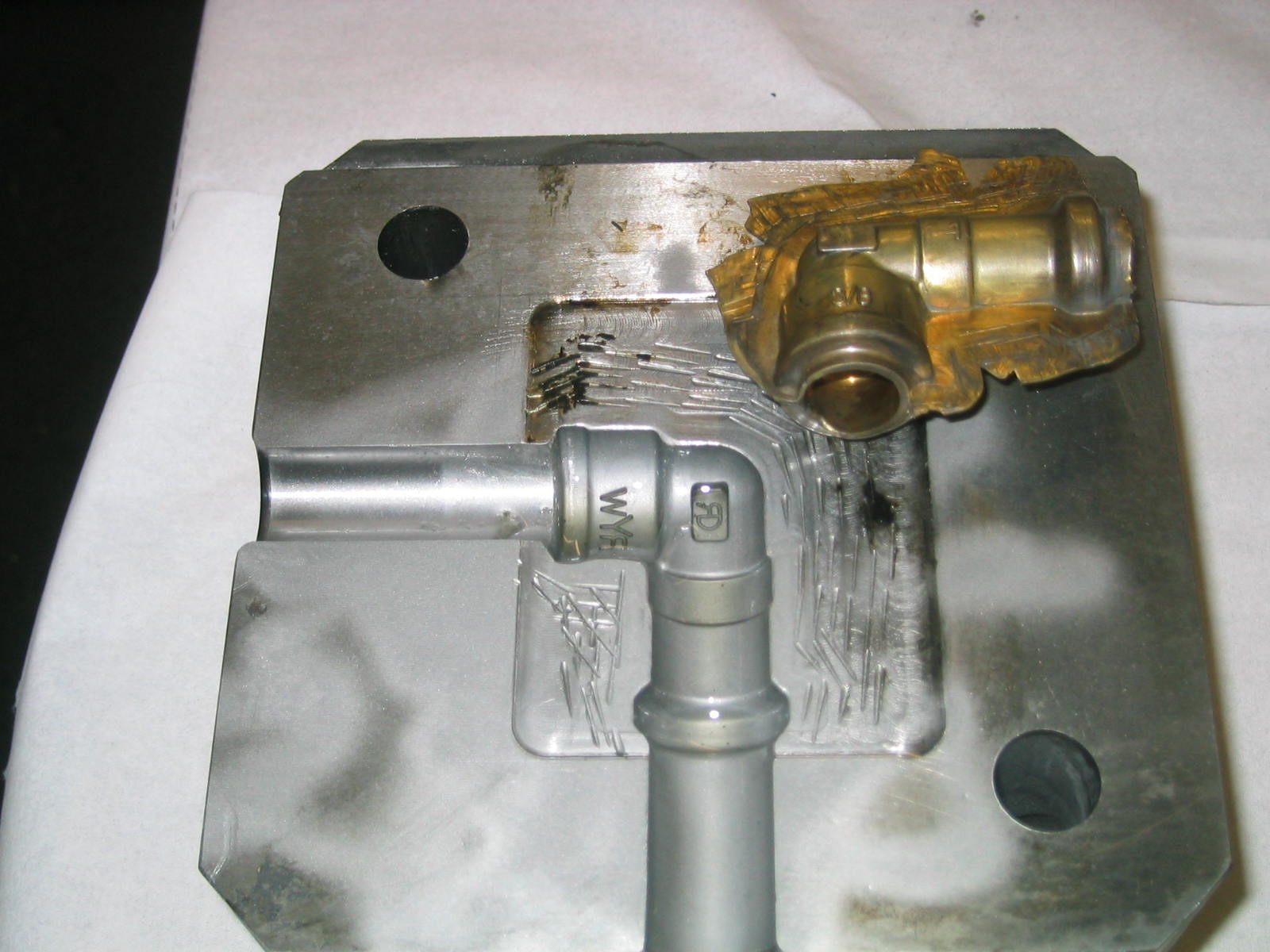

An example of an aluminium prototype injection mould tool that we have machined c/w all bedding off inserts machined on our CNC milling m/c, manufactured from solid to eliminate the need for additional operations producing inserts or Spark Eroding. | |